Diy steel foundry

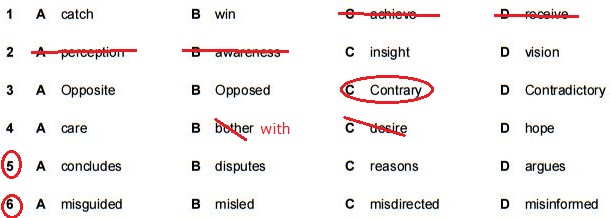

If you've ever been to the movies, admired a piece of sculpture, marveled at detailed architectural ornamentation or used a telephone; then you've encountered the handiwork of people who use Smooth-On rubbers, plastics, foams and other products to turn their ideas into 3-dimensional reality. A good opportunity to see "The Artful Bodger's Iron Casting Waste Oil Furnace" (what a mouthfull!) in action! Colin . How to Melt Soda Cans With A DIY Metal Foundry Sand Casting Aluminum Metal Casting Metal Projects Metal Crafts Welding Projects Craft Projects Fantasy Dagger Homemade Forge Recycling Center There are countless things you can do with leftover aluminum cans. Almost any material can be melted into the liquid alloy can be used for casting, such as steel, a variety of aluminum alloy, copper alloy, iron alloy, platinum alloy castings and so on. Greensand casting is the most economical method to reproduce items in metal. 9 users here now.

A homemade cast aluminum lathe is one thing, but one with cast iron parts would be even better. com Backyard Metal Casting Epic Fail YouTube via youtube. Home made steel melting furnace. com,DIY Foundry – DIY Metal Foundry Builds & Sand Casting MENU Tutorials Resources Foundry & Sand Casting Shopping List Video Tutorials Build Your Foundry Sand Casting Projects Random Customize Simply Eve Scrap metal has been salvaged and reused since the early ages of metal working. Budget Casting Supply LLc Featuring Supplies for the Commercial Foundry and Home Hobby Foundry.

Until I decide to invest in good tools I needed a cheap solution. He melts down aluminum cans into ingots for casting and creating metal works in his backyard. Smelting metal from ore would also be on-topic here, unless there turns out to be a more specific and active smelting subreddit. The burner is built with scrap steel, a brass door knob, a Volkswagen oil pump, and an old DeWalt cordless drill. It's possible to perform metal casting work as a hobby in a home workshop.

By dan_m, December 15, 2011. Make a Mini Foundry for Cheap That Can Melt Soda Cans. Melting aluminum, brass, or other mid-temperature melting point metals requires over 1000 degree temperatures. A good refractory crucible can be purchased for about $30 online. DIY Foundry.

How to build a medium-sized foundry An old propane tank makes an excellent container for a medium-sized foundry. This page shows in detail how to build the Kwiky all fuel foundry burner. If you are not used to this process, then further research may be needed. My goal is to take advantage of my Harbor Freight 80A inverter constant-current DC stick welder as the power source. Our mission at PMC Supplies is to provide our vast customer base with a one-stop shopping experience for quality casting equipment and supplies.

The sand mold is in an uncured state as the metal is being poured. We pride ourselves on unsurpassed quality, customer service, and on-time delivery, as evidenced by our 100% customer retention rate. Most small scale sand casting is done with "green sand" that is, a sand bound with clay and water. This is an aggregated site. 75GPH nozzle is in the mail).

Sign up *Usage of the SFSA Wiki is restricted to SFSA members, US government and their contractors. 2. Let’s melt some metal! The King Of Random has done it again by building a homemade mini metal foundry with a steel crucible. This is just to see if I like casting metal. Top-View of Foundry Metal casting projects are great because you can do them on your own or with a group of people.

At least until I decided if this was something I was going to keep doing. Feel free to check my YouTube channel where I provide detailed explanations, tips & tutorials for best backyard aluminum casting methods, homemade foundry equipment & of course the importance of safety when working with molten aluminum. DY-KAST Supply is your source for Die Casting, Foundry Supplies, and Forging supplies. Difficulty Level (Easy, Medium, Hard, Insane): Easy Process: I've used a square corn bread muffin pan to cast my left over aluminum but because the material is so thin, the 640 degree (C) molten metal warped the muffin pan quite badly to the point where it was hard to get the ingots out so I decided I was going to make a more permanent solution. Lost-PLA Casting of Aluminum.

Step 9: Finishing Touches and First Establishing a Compact Foundry. A page listing links, companies I've dealt with and books I've found useful. Casting is used to produce train wheels and other durable metal components. Metal casting involves the heating of metals to make them into a liquefied, molten material. 2 Fire Brick Metal As an alternative to a crucible for holding the molten material, metal ingots can be dumped directly into the refractory if you build the foundry with a second, smaller metal pipe, located at the bottom of the foundry and angled downward, that acts as a “drain” for the molten metal to pour from.

The solidified piece of metal also referred to as the casting or ingot is then released from the mold to complete the process. It's made of A356 aluminum, perfect for casting; more silica, better flow. The process is fairly straightforward: you make a pattern of what you want to cast, then use the This is a link to a clip from the program showing the casting "VIDEO" The program is called "The boat that Guy built". DIY Metal Melting Furnace. Metal Casting In relation to metalworking, casting is the process in which metal is liquefied and poured into a mold which is then cooled and solidified into the shape of the mold’s cavity.

The Advantages of Metal Casting. com Backyard Metal Casting And Homemade Forges Image With Mesmerizing via wli-inc. making a foundry capable of melting steel If this is your first visit, be sure to check out the FAQ by clicking the link above. If you’re interested in melting metal, and you totally should be because it’s basically the most fun way to recycle soda cans, The Art of Weapons details how to make an electric foundry for Aluminum is a very versatile material and I would like to promote the awareness of aluminum recycling via different metal casting projects. Our lives are filled with cast metal products.

NOTICE: Owner Retiring – This website Domain For Sale! Serious Buyers Only Use > Contact Form The Foundry Zone provides a DIY Pro Tools (Do It Yourself) and a Free Information Center for Metal Casting and How to Scrap Metal Recycling for Raw Material and Cash Business Profits. The temperatures get as high as 17-1800 degC, enough to melt steel. Overview of metal casting for beginners 1 2. This will channel any molten metal down into the drain in the event of crucible failure. The downside is that the sand is a soft mold and can collapse or shift during casting, leaving an unusable cast.

Metal Forge Refractory Cement Watch blacksmith Jason Northguard hammer a metal leaf out of square stock. Home metal casting information for building a foundry and melting metal in your backyard. When the foundry body and lid molds dry; drill two holes up to 1″ diameter into the button of foundry body which uses for gas and air supplying pipes. – The crucible I used was steel, but it’s important to note that steel can be soluble in molten aluminum. The remaining sand that clings can be cleaned off with a brush.

www. A place where you can - create - design - and convert your creative ideas into a solid metal reality. Grant Thompson decided to build a homemade metal foundry from a mixture of 50% plaster of paris and 50% play sand. We offer a wide variety of products including: Ladles, Skimmers, Electric Infrared Die Heaters, Die Clamps, T-Slot Bolts, Nuts, Washers, Nozzle Gaskets, Thermocouples, Tongs, Cleaning Tools, Pyrometers, Sow Molds, Ingot Molds, Portable Pumps, Mixers, Non-Ferrous Melting Equipment, Soft Metal Melting Furnaces Welcome to PMC Supplies: An international and domestic supplier of tools and equipment for Casting Metals and Jewelry Making. With highly experienced foundry design engineers (averaging some 30 years in the industry), and our familiarity with every aspect of the metal casting process, we augment our domestic resources with extensive worldwide consulting engineering affiliates.

One on the lid to open and close the furnace and one on the tank to serve as a support to pick up the furnace and carry it around, together with the hinge handle on the back. And if you use a lot of brake rotors for your homebrew cast iron lathe, it might require special handling. Backyard Foundry and DIY Metal Casting information for the Home Metal Casting group can now be found on a new page all about Home Metal Casting. I can still remember being amazed the first time I learned it was possible to melt metals like aluminium, copper and even steel at home to form bespoke metal objects. Let us put our experience to work for you.

The Foundry DIY (Do It Yourself) Zone, How to Metal Casting and Scrap Metal Recycling with Foundry Furnace / Melting Furnance, Information and foundry supplies The Foundry Zone Equipment - Supplies - Resources For Sand Casting, Mold Making, Pewter Casting POURING TOOLS For Heating and Pouring Metal BENCH TOOLS VACUUM CASTING DIY Castings. What is cool about his series is that the tool you make in volume 1 allows you to make the tool from volume 2, and so on… This leapfrogging of technology builds your skills to complement your shop. Step 3: Things You'll Need. Here are a few examples and explanations to get you started with this hobby. There are hundreds of good web sites out there dealing with home foundry work, I'm only listing ones I have had personal dealings with.

. 1. The functionality is founded on ideas I collected while searching the internet for foundry designs. Metals such as steel, iron, aluminum, and copper can be recycled an infinite number of times, because their metallic properties do not deteriorate with repeated melting and casting. Core Box Air Release Vents & Accessories.

com If you are searcing for something specific on my site, you can use the google search bar above to find it. We want to help you to discover how to cast metal in the back yard hobby foundry. In this video we set up and demonstrate just how easy it is to melt brass. com Equipment Foundry Tools Crucibles Flasks Flux Injector Vacuum Tester Furnace Refractory Products Heating Elements & Controls Advanced Mass Spectrography Service: Nikkin Flux Corp. Off to the Foundry (garage) The sand pretty much falls off the castings.

How to Make the Mini Metal Foundry Step 1: Watch the Video. 3-1000mm, the length varies from a few millimeters to ten meters, and the quality can be from a few grams to more than 300t. If you’ve ever longed for a custom mold of your own, this easy-to-follow molding putty recipe is a great place to start! Refractory Cement For Your Foundry Furnace can be a REAL B*TCH! If you don't get the recipe just right, you could have the walls crumble at full temp, or melt into a pile of glass and clay. 1 Mini Homemade Metal Foundry Furnace Forge propane charcoal DIY Lid Pt. Casting molten metal in a foundry first involves transferring the metal from a furnace to a ladle, before pouring the metal into molds.

backyard-foundry. To build a simple home made furnace for casting metals you need to meet some simple design requirements and use appropriate materials. Alibaba. There is a hobby that will give you the opportunity to play in the sand again: green sand casting in the home shop. Using more iron strips we made 2 more handles on the front side.

Background: For as long as I can remember, I’ve been intrigued by the idea of melting metal and making things with it. Next we made a hole on the side of the tank, closer to back. Freeman Leather Fillets. The Babbington burner atomizes the waste oil fuel before injecting it into the furnace and make for much more controllable and stable combustion. Should you attempt to build a furnace like this one, I am not responsible for ommissions, mistakes, or errors that may lead to injury or death.

Step 8: Lid & Supply Port. They make great gifts, or fixtures in your home and you can save a lot of money. Included with sets having a silicone rubber mold is a packet of very fine graphite powder which improves the metal flow into the mold and aids in the release of the casting. They sell scrap remnants for about a dollar a pound. A home foundry is different from a commercial foundry in the way it is generally setup using things and equipment that are easily available in the market and can be used to perform simple metal casting works.

The metal recycling industry specializes in retrieving metal from obsolete objects so that scrap metal does not end up in landfill sites. There’s a bit more work involved if you want to make aluminum alloys, but this survival DIY skill is worth your time. If you wanted to Backyard Metal Casting and Homemade Forges: For thousands of years, man has worked metals. Cast iron from the home shop opens up a lot of possibilities. I decided to make a cheap DIY crucible to last one or two casting sessions.

How to make a Metal Foundry Easy build High Temperature Home Made Metal Foundry. Wide suitability The metal casting process is almost free from the restrictions of the size, thickness and shape of castings, casting wall thickness can be up to 0. Drill a hole through the drum and hardened Perlite and run the steel pipe through the hole into the foundry’s center cavity to form the blow pipe. How to Build a Metal Melting Furnace for Casting. The sand which is burnt needs to be reclaimed in a muller for this type of sand.

DIY Induction Foundry Initial Approach Most of the DIY induction heating projects I have seen tackle the entire power supply from scratch (including voltage and current regulation). Making a cast of something involves pouring a liquid into a mold and allowing it to harden. Think of all the things you could provide your group with if you have a foundry ! This is a link to a clip from the program showing the casting "VIDEO" The program is called "The boat that Guy built". . Due to some of my experiments in filling 1lb propane tanks, I have some empty tanks Grant Thompson, a maker (and exploder) of awesome things, has been getting a lot of questions lately about how to build a metal foundry — a mini inferno to make metal castings in.

The aluminum casting turned out very well and surprisingly ;-), the handle is made from scrap metal such as bolt, nuts metal loop and old fishing chain. A damaged alloy wheel is useless --except to you! Hammer it into pieces. Casting molds are a pretty handy thing to have around, especially if you’re in the habit of playing with resin or liquid polymer clays. From both an environmental and economical standpoint, recycling metal is extremely effective. About Smooth-On, Inc.

NOTE: Please understand that many of these pages have lots of pictures and because of this will take sometime to load completely. Although some of the technology to work metals is relatively recent, the initial human drive to create is still with us. Recommendations. Flex-Gate Flexible Gating. Latest updates.

The latest upgrade to the foundry furnace is a Babbington style burner for the waste oil. The process is fairly straightforward: you make a pattern of what you want to cast, then use the View diyfoundry. The industry's highest quality leather fillets. This is the easiest way I have found to make a great foundry burner for back yard metal casting. A wide variety of diy metal casting aluminum foundry options are available to you, such as home decoration, business gift, and holiday decoration & gift.

This foundry is an original design, which comes after months of experimenting, and over 10 different prototypes. A DIY foundry is a good option to easily melt soda cans. Step 7: Making It Professional. But the best source is a metal retailer warehouse like Industrial Metal Supply in the San Fernando Valley. Except for the crucible and a few random buckets, Thompson suggests it won't cost you more than $20 to build.

He uses a variety of tools including a propane forge, anvil, and power hammer. This article is an account of constructing a small bronze casting furnace. You may have to register before you can post: click the register link above to proceed. A large selection of brass, steel, aluminum, and nylon air release DIY Mini Metal Foundry This is one of those projects that could be a major boost to your SHTF plans. View diyfoundry.

Move Over Aluminum: Cast Iron for the Home Foundry. When the mold is fired in a kiln, the wax is burnt out or “lost”; then metal parts can be cast in the mold. Many of the metal objects we take for granted – train wheels, trailer hitches, lamp posts, large scale industrial equipment, and even sculpture – are cast in a foundry. I made a small furnace for casting iron and stainless steel. Disclaimer.

com Backyard Metal Casting And Homemade Forges via instructables. It is a bad idea and could be dangerous to melt casting metal over your stove or a hot plate. English (US) · Español · Português (Brasil) · Français (France) · Deutsch. It’s possible that when you lift the crucible out of the foundry, the bottom can dissolve out and drop molten aluminum onto you feet and onto the ground. Sand casting using green sand is quick and inexpensive since the sand can be reused.

Spike ball for zombie apocalypse - In this video I will show you the stages of how I made an aluminum spike ball using lost foam casting method. Mold your master object with either ComposiMold or ImPRESSive Putty. Anyone ever considered making a small Siemens-Martin furnace? It is a regenerative furnace which basically means you use a heat exchanger to extract heat from the exhaust gas and use it to heat the inlet air prior to combustion. Effort Foundry is a supplier of high-integrity steel castings for the pump, valve, nuclear, power generation, and military industries, as well as other general manufacturing applications. This may not be a good option for people who are not familiar with melting metal.

How to make a Large $50 Mini Homemade Metal Foundry Furnace Forge propane or charcoal DIY Pt. Metal casting is an amazing, however, quite a simple process that can be used to make a variety of things, with your skill and Design plan for the well tank aluminum home foundry. When word got around that I was casting metal, it seemed the whole dang county was beating a path to my door, looking for me to make kitchen utensils, repair tool parts or fabricate structural members (for wind plants, greenhouses, geodesic domes and more) in exchange for goods, services or cold cash. Jeshua Lacock of Boise, Idaho, used the lost-PLA technique and a homemade furnace to cast aluminum parts for his home-built CO2 cutting laser, The latest upgrade to the foundry furnace is a Babbington style burner for the waste oil. Metalcasting at home with mostly homemade equipment and a small budget.

Metal casting tools is one of the most popular things that people enjoy doing. With a kiln or a foundry, things work a little different from a modern kitchen gas oven. Once you've got it all set up, you can melt soda cans and other metals, NOTICE: Owner Retiring – This website Domain For Sale! Serious Buyers Only Use > Contact Form The Foundry Zone provides a DIY Pro Tools (Do It Yourself) and a Free Information Center for Metal Casting and How to Scrap Metal Recycling for Raw Material and Cash Business Profits. It's an inexpensive and fun project to take on at home, but there's some stuff ya gotta know first. Step 4: Refractory Mix.

For this video we tried to use a material which did not seem to flow very well but got excellent results from the home made casting sand. Using very common and inexpensive material Gingery shows the reader how to make a foundry to melt and cast aluminum. It will melt aluminum cans with over 1000 degrees of heat provided by regular old charcoal and a hair dryer. DIY Foundry For Backyard Metal Casting Part I YouTube via youtube. The Details.

Casting aluminum at home may seem like an odd hobby, but it can be a safe way to make the metal objects that you need or want. DSL/CABLE shouldn't have any trouble, but people using dialup connections may have to wait for them to load. com This page shows in detail how to build the Kwiky all fuel foundry burner. This same technique can be used with PLA filament. Grant Thompson, “The King Of Random,” has created a reusable backyard foundry that is really impressive.

the diy metal casting process 1. Step 2: The Mini Metal Foundry. Make a wax or ComposiMold casting of the object using the mold you made (See our disclaimer before continuing) Insure that you work very carefully with anything that gets as hot as this does and be sure to read the presenter’s warnings about the temperatures contained in the featured article right below the DIY video. Just add water and the greensand can be used thousands of times to cast aluminum or other alloys. 26 replies DIY super-cheap refractory to melt steel in oil burner The King of Random Videos DIY Micro Metal Foundry.

Refractory Cement For Your Foundry Furnace can be a REAL B*TCH! If you don't get the recipe just right, you could have the walls crumble at full temp, or melt into a pile of glass and clay. How to Make the Mini Metal Foundry The "King of Random", as Grant Thompson (previously) is known, recently shared a video on how to make a simple and inexpensive mini metal foundry for melting pop cans and casting aluminum. We do not manufacture equipment. Our professional services are, therefore, unbiased. SFSA Wiki (members only)* Steel Castings Handbook information, steel casting discussion forum, and more, are available online in the SFSA Wiki.

Welcome to the metalcasting foundry, a subreddit for the discussion of all manner of metal casting and foundry work, whether in the backyard or on a commercial scale. Almost all of them used a burner design called the "Reil Burner," which has the distinct DIY advantage of being constructed almost entirely from All of our Starter Casting Sets include an electric melting pot. Guide to DIY Metal Casting. In a kiln, or a clay oven, the heating is instead more from radiation: the flame heats the air, Discover The Old World Metal Foundry Craft. com offers 489 diy metal casting aluminum foundry products.

If you are interested in doing your own metal casting, there are several books, magazines and even classes that can help to guide you if you are a beginner. com,DIY Foundry – DIY Metal Foundry Builds & Sand Casting MENU Tutorials Resources Foundry & Sand Casting Shopping List Video Tutorials Build Your Foundry Sand Casting Projects Random Customize Simply Eve The Advantages of Metal Casting. Melting aluminum for raw materials is a good way to set yourself up when a global crisis comes down. You may never have heard of us, but you've seen our products at work. In a gas oven, much of the cooking occurs in the form of convection: the flame heats the air, and the hot air cooks your food.

I am putting it here for educational purposes only. The electric arc furnace operates as a batch melting process, producing batches of molten metal known “heats”. Strong, resilient, flexible runners for use on pattern plates . This is the first of many planned casting projects. MENU HOME DIY Metal Casting Projects.

When it comes to the art of metal casting, there are many project that you can do on your own. has been selling products for the metal casting industry for more than 20 years. My Home Foundry and How To Make Them. A simple DIY foundry is made to be reusable and requires the use of a 5-gallon bucket. Due to some of my experiments in filling 1lb propane tanks, I have some empty tanks Cast the foundry lid with up to 5-7 cm thickness of concrete with wool steel.

You'll also need a strong steel cup for the crucible (Thompson uses the bottom half of an empty fire extinguisher). A word of warning: This foundry can reach temperatures well over 1200 degrees Fahrenheit! Make sure you use all the proper safety equipment before you attempt to use your foundry. About 8% of these are metal crafts, 3% are casting, and 1% are cast & forged. Step 5: Clean Up. Get Medieval: How to Build a Metal Forge.

Steel and brass alignment dowels for use with core boxes and mold halves. A special place of your own. budgetcastingsupply. My email platform stopped allowing me to send out my e-zine so I have set up a Google+ site to keep everyone updated with my latest projects and to interact. It uses the same burner as my aluminum furnace but takes about 2 hours to heat up( a .

For those brittle alloy materials with low plasticity (such as ordinary cast iron), casting is the only feasible forming process. Step 6: Making the Crucible. Short, thin rods melt quickly. The proceed with caution! How To Make The Mini Metal Foundry. diy steel foundry

, , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ,