Astm d3350

About SIS SIS – Organisation. It is not the function of this specification to provide specific engineering data for design purposes, to specify manufacturing tolerances, ASTM D3350 - 06 . For Annual Book of ASTM Standards volume information, refer to the standards Document Summary page on the ASTM website. pdf), Text File (.

4. This document describes the standard specifications and features related to Georg Fischer Central Plastics' injection molded PE4710 (formerlyPE3408) Butt Fusion Fittings for pressure piping systems. Contact us svenska Login.

It is not the function of this specification to provide specific engineering data for design purposes, to specify manufacturing tolerances, or to determine suitability for use PE3408 as defined by ASTM D3350-96 and D3350. Fold an end of the specimen to create a tab parallel to the plate. Standard Specification for.

D. A All Design Flow (PE) IPS/DIPS pipe shall be manufactured from a PE100/4710 high density copolymer resin meeting the requirements of ASTM D3350 and D3035. Density, Natural D1505 0.

viagra 100mg ASTM D3350-12 covers the identification of polyethylene plastic pipe and fittings materials in accordance with a cell classification system. Scope* 1. It also provides improved ability to detect damages and scratches.

Skip to the beginning of the 2. The yellow shell helps reflect solar heat, enabling retention of higher strength ambient temperature properties. An important feature of this designation code is that it identifies the maximum recommended hydrostatic ASTM-D3350 › Standard Specification for Polyethylene Plastics Pipe and Fittings Materials.

Scribd is the world's largest social reading and publishing site. This document has been replaced. The removal of these PE compounds does not affect pipelines that are in service.

f. astm. ASTM D 3350—08 Specification for Polyethylene Plastic Pipe and Fitting Materials (PDF Download) Skip to the end of the images gallery.

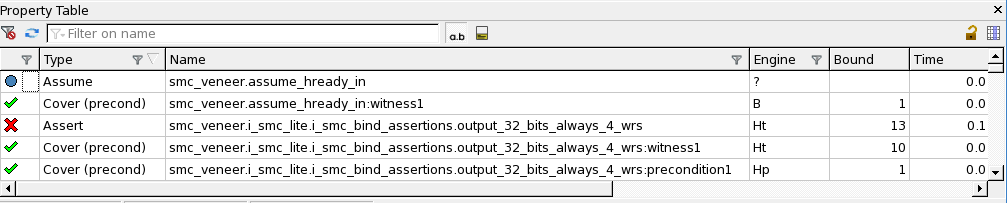

3. Previous editions of ASTM D3350 resulted in cell classifications of 345464C and 345564C. ADS HDPE drainage products are used in a wide variety of end-use applications: • Storm and sanitary sewers 1.

1 This specification covers the identification of polyethylene plastic pipe and fittings materials in accordance with a cell classification system. ” • Cell Classification PE445574C per ASTM D3350 • NSF/ANSI Standard 14 Certified for Potable Water Contact ASTM D3350-12 Standard Specification for Polyethylene Plastics Pipe and Fittings Materials. ASTM D3350 - 06 .

hIGh-DEnSITy PolyEThylEnE WATER 5 ProPErTY UNIT TEST ProCEDUrE TYPICAL vALUE MATErIAL DESIGNATIoN — PPI -Tr4 Pe 4710 CELL CLASSIFICATIoN — ASTM D3350 445574C DENSITY g/cm3 ASTM D1505 0. Data is based on S4 tests conductedo n 12-inch SDR 11 pipe. While the American Water Works Association (AWWA) is expected to publish its AWWA M 55, Manual for the Design and Installation of Polyethylene Pipe in Water Applications later this year, the material is tape to ensure conformance with ASTM F714 or ASTM D3035, whichever is applicable.

HDPE (3608) HDPE 3408/3608 IPS & DIPS PRESSURE PIPE (4, 6”) Scope: This submittal designates the general requirements for High Density Poly-Ethylene Pressure Pipe from compound with a cell classification PE345464C as defined in ASTM Standard D-3350. 16 kg) D1238 0. c.

Standard Specification for Polyethylene Plastics Pipe and Fittings Materials - ASTM D3350. PE4710 pipe produced at WL plastics is certified with the National Sanitation Foundation (NSF) for both NSF 14 and NSF 61 standards. This specification covers the identification of polyethylene plastic pipe and fitting materials.

b. PE compounds and material designations resulting from changes in Specification D3350 and PPI TR-3 are addressed in Section 5. The pipe shall meet the requirements of cell classification PE345444C standard PE code designation PE3408 as defined by ASTM D3350-96 and D3350.

ASTM D3261 Standard Specification for Butt Heat Fusion PE Plastic Fittings for PE Plastic Pipe and Tubing. The resin has a cell class of PE 445474C according to ASTM D3350. Color and ultraviolet stabilizer, thermal stability, brittleness temperature, density, tensile strength at yield, and elongation at break shall conform to this specification.

• Hydrostatic Design Basis 1,600 psi @ 73°F (23°C) and 1,000 psi @ 140°F (60°C) per ASTM D2837 • Color & UV Stabilizer: Black with 2% min Carbon Black per ASTM D3350 • Heat Fusion Joining as per ASTM F2620 and PPI TR-33/TR-41 • Installation as per AWWA M55 and PPI PE Handbook, 2nd edition astm d3035 - SDR – Iron Pipe Size (IPS) Controlled Outside Diameter For more information regarding Endot EndoPure or any Endot product, please contact your local Endot Sales Representative or contact us directly at 1-800 – 44 ENDOT (800-443-6368) or email to info@endot. 959 MELT INDEX g/10 minutes ASTM D1238 < 0. For more information, please visit info.

The 12- through 60-inch (300 to 1500mm) virgin pipe material shall be Hancor Resin 8 TM, which is a slow crack resistant STANDARD CONSTRUCTION SPECIFICATIONS FOR SANITARY SEWERS DIVISION 50 SECTION 50. described in ASTM D3350-04 (324420C in ASTM D3350-00) and 435400C for 12- through 60-inch (300 to 1500mm) diameters, as defined and described in ASTM D3350-04 (335400C in ASTM D3350-00). Standard Specification for Polyethylene (PE) Plastic Pipe (DR-PR) Based on Controlled Outside Diameter1 This standard is issued under the fixed designation D 3035; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision.

View the most recent version. Formolene® E6210A is a bimodal high molecular weight high density resin that is designed for the most demanding requirements of pressure pipe applications. All Design Flow (PE) IPS/DIPS pipe shall be manufactured from a PE100/4710 high density copolymer resin meeting the requirements of ASTM D3350 and D3035.

The pipe has an ASTM D3350 Cell Classification of PE445574C and is available in pressure class 200, 250, and 335 psi. Search Search Description of ASTM-D3350 2014 1. 20: Plastics Pipes Fittings.

ASTM D4703, Annex A1 or ASTM F1473. ASTM D3035 Standard Specification for Polyethylene (PE) Plastic Pipe (SDR-PR). 1.

pdf - Download as PDF File (. Pipe shall be manufactured to SDR 11 or SDR 17 dimensions with a pressure rating of 200 psi or 130 psi respectively when measured at 68°F. (230 C) Cell Classification per ASTM D 3350 - 445574C and 445576 C HDB Ratings/PP1 TR4: HDB is established @ 73.

Materials shall be manufactured by molding and extrusion of polyethylene plastic in the form of powder, granules, or pellets. Browse related products from ASTM International. Secure the end of the plate furthest away from the tab to the moving grip.

960 g/cc (black) Melt Index ASTM D1238 . Dura-Line is ISO 9001 certified and PolyPipe is qualified using exacting laboratory procedures and test methods, and a consistent uncompromised quest for design and manufacturing excellence. The 12- through 60-inch (300 to 1500mm) virgin pipe material shall be Hancor Resin 8 TM, which is a slow crack resistant The ADS Flared End Section shall be high density polyethylene meeting ASTM D3350 minimum cell classification 213320C; contact manufacturer for additional cell classification information.

standard by ASTM International, 04/01/2012. org Back to Top on the cell requirements of ASTM D3350, a simpler, short-hand, ASTM recognized material designation code is commonly used for quickly identifying the most significant engineering properties of a PE pipe material. classification PE345464C as defined in ASTM Standard D-3350.

1 Scope of Work The Work covered by these Specifications consists of providing all plant, labor, equipment, supplies, material, transportation, handling and storage, and performing all operations 99 2 Bu tFings:i45°FiEgu ts According to ASTM F1290-90, electrofusion is defined as “a heat fusion joining process where the heat source is an integral part of the fitting, such that when an electri- . The pipe conforms to ASTM F714, AWWA C906, ASTM D3035, AWWA C901, NSF 61 and FM 1613. The PE4710 material conforms to ASTM D3350 with the cell classification of 445574C/E and is listed with the Plastic Pipe Institute’s (PPI) TR4.

040. The standard cell class for ASTM F2160 conduit is PE334480C or E. The resin provides an excellent balance of physical properties and extrusion processability.

e. 63 design factor at 23 degrees Celsius in accordance with ASTM D3350 and the stress rating policies in the Plastics Pipe Institute’s PPI-TR-3. We offer comprehensive hydrostatic pressure programs for plastic pipes, from initial testing and regression analysis to Minimum Required Strength (MRS) and Hydrostatic Design Basis (HDB) services.

Cell Classification 445574C ASTM D3350 Process Injection Molding Fittings meet AWWA and ASTM-D2513 & ASTM-D3261 requirements, and are ASTM D3330 describes six methods used to test the adhesion strength of pressure sensitive tape. txt) or read online. ASTM D3350-14, Standard Specification for Polyethylene Plastics Pipe and Fittings Materials, ASTM International, West Conshohocken, PA, 2014, www.

08 g/10 min Flexural Modulus ASTM D790 > 120,000 psi Tensile Strength ASTM D638 Type IV > 3500 psi SCG (PENT) ASTM F1473 > 2000 hours HDB at 73OF ASTM D2837 1600 psi Color; UV stabilzer ASTM D3350 Black 10/15. For removed designations, refer to previous editions of Specification D2239, Specification D3350, PPI TR-3 and PPI TR-4. Heat fusion may be used for joining this pipe but has limited tooling availability.

FM approved products are manufactured in accordance with AWWA C906, ASTM F714 and FM Approval Standard 1613. ASTM D3350-Polyethylene Plastic Pipe and Fittings Material ASTM D2239-Polyethylene (PE) Plastic Pipe (SIDR-PR) Based on Controlled Inside Diameter ASTM D2447- Polyethylene (PE) Plastic Pipe, Schedules 40 and 80, Based on O. Based on controlled outside diameter.

ASTM D3350:06 Withdrawn ASTM D3350:10 Withdrawn: Superseded by: ASTM D3350:12 Withdrawn: Number of pages: 7 Price: NOK 1 Fittings will be cast iron, steel, one piece injection molded plastic fitting, or fabricated from plastic pipe and one piece injection molded plastic fittings. While the American Water Works Association (AWWA) is expected to publish its AWWA M 55, Manual for the Design and Installation of Polyethylene Pipe in Water Applications later this year, the material is • ASTM F714, “Standard Specification for Polyethylene (PE) Plastic Pipe (DR-PR) Based on Outside Diameter. The manufacturer shall certify that the material meeting this specification has exceeded 5,000 hours without failure when tested under ASTM F 1248, and has a hydrostatic design basis of 1,600 psi at 73°F and 800 psi at 140°F when tested under ASTM D 2837.

2 For referenced ASTM standards, visit the ASTM website, www. The six digits equate to the specified level of performance required in six separate physical properties defined within the standard. pdf Designation: D3350 − 14Standard Specification forPolyethylene Plastics Pipe and Fittings Materials1This standard is issued under the fixed designation D3350; the number immediately following the designation indicates the year oforiginal adoption or, in the case of revision, the year of last revision.

(A) High Density Polyethylene (HDPE) Pipe. We test per a variety of standards, including ASTM D2837, ASTM D2992 and ISO 9080. ASTM D3350.

Pipe wall thickness shall be measured at 12 equally spaced locations around the circumference at both ends of the pipe to ensure conformance with ASTM F714 or ASTM D3035, whichever is applicable. Both the natural and the black versions of TRB-432 have a minimum required strength of 1,450 psi or 10. - ASTM D2122 - ASTM D2122 - ASTM D618 - ASTM D883 - ASTM D883 - ASTM D3350 - ASTM D1693 - ASTM D3350 - ASTM D1693 - ASTM F667 - ASTM F412 - ASTM F667 - AASHTO Standard Specification for Highway Bridges Referenced Standards: Referenced Standards: SPECIFICATIONS Timewell participates in and complies to all production standards set forth by Standard Specification for Polyethylene Plastics Pipe and Fittings Materials - ASTM D3350.

ASTM D 3350 Cell Classification for PE 3408, 345444C or 345464C. HDPE Pro Fittings is a manufacturer of HDPE fabricated fittings from 3” to 24” IPS that also performs value added services such as dual containment pipe and fittings, perforate pipe, manufacture man holes to include just a few. ASTM D 790: Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials i.

PE 4710 Resin formulation - These materials also meet the requirements for a PE 3408 as per ASTM D3350-02a Specifications: ANSI/AWWA C901 CTS DR 9, PC 250@ 800F. For example, the cell classification for Performance Pipe’s standard extra high Designation: D 3350 – 06. Search Search ASTM D3035, Standard Specification for Polyethylene (PE) Plastic Pipe (DR-PR) Based on Controlled Outside Diameter.

(270 C) ASTM D2737 - CTS DR 9, 250 PSI @ 730F. ” • ANSI/AWWA C906, “Polyethylene (PE) Pressure Pipe and Fittings, 4” to 65” (100mm to 1650mm), for Waterworks. com ASTM A635/A635M-14 Steel, Sheet and Strip, Heavy-Thickness Coils, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, and High-Strength Low-Alloy with Improved Formability, General Requirements for HDPE Specifications and Standards High-density polyethylene (HDPE) solid wall pipe has been used in potable water applications since the 1960s.

This standard is issued under the fixed designation D 3350; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. Shall meet the requirements of ASTM F714 Polyethylene (PE) Plastic Pipe (SDR-PR) based on outside diameter, ASTM ASTM D3350. Virgin material for pipe and fitting production shall be high density polyethylene meeting ASTM D3350 minimum cell classification 324420C for 3" – 10" (75 – 250mm) diameters or 335420C for 12" – 24" (300 – 600mm). ![]()

It is formulated with carbon black and/or ultraviolet stabilizer for maximum protection against UV rays for added assurance. ASTM D 1505: Standard Test Method for Density of Plastics by the Density-Gradient Technique h. ASTM D 2239: Polyethylene (PE) plastic pipe (SIDR) based on controlled Inside Diameter (ID).

com astm d3350 standard specification for Polyethylene Plastics Pipe and fittings materials astm d1238 standard test method for melt flow rates of thermoplastics by Extrusion Plastometer astm d1603 standard test method for carbon Black content in olefin Plastics aasHto m252 corrugated Polyethylene drainage Pipe, 4 to 10 in. The pipe has an ASTM D3350 Cell Classification of PE445574C when using HDB or PE445576C using MRS. ++ Material complies with NSF/ANSI 61 health effects requirements when tested at temperatures up to and including Domestic Hot (140° F).

2) Joint strength: Equal to or greater than pipe strength. a) In case of conflicts between ASTM D2657 and approved submittals or if the ASTM reference is nonspecific, follow approved submittals. 45 (Plastic fittings) Material Designation ASTM F714 PE4710 Cell Classification ASTM D3350 445574C (black) Density ASTM D1505 .

astm d3350-14 Standard Specification for Polyethylene Plastics Pipe and Fittings Materials 1. • PE3408/PE4710 Fusion fittings are manufactured and tested to the requirements of ASTM D2513 and ASTM D2683 and are compatible for heat fusion with any pipe and or fitting manufactured from a like or similar resin. 1 ASTM Standards: D 618 Practice for Conditioning Plastics and Electrical Insulating Materials for Testing D 792 Test Method for Density and Specific Gravity (Rela-tive Density) of Plastics by Displacement D 1238 Test Method for Flow Rates of Thermoplastics by Extrusion Plastometer D 1505 Test Method for Density of Plastics by the Density- ASTM F2206 (Fabricated Fittings) Key Benefits of PLATINUMSTRIPE™ 1800 PE-RT Piping Systems Higher permissible operating temperatures compared to standard PE4710 products The ASTM D3350 consists of a series of six digits followed by one letter.

d. 40F. Withdrawn.

ASTM D3350—2012e1 Standard Specification for Polyethylene Plastic Pipe and Fitting Materials (PDF Download) Skip to the end of the images gallery Skip to the beginning of the images gallery HDPE Specifications and Standards High-density polyethylene (HDPE) solid wall pipe has been used in potable water applications since the 1960s. The molecular weight category shall be extra high (250,000 to 1,500,000) as per the Gel Permeation Chromatography determination procedure with a typical value of 300,000 to 330,000. It does not provide specific engineering data for design purposes, to specify manufacturing tolerances, or to determine suitability for use for a specific application.

2. ASTM D3035: Polyethylene (PE) plastic pipe (SDR) based on controlled Outside Diameter (OD). NEMA TC 7-2013-Smooth Wall Coilable Electrical Polyethylene Conduit A standard used in power applications.

• ASTM D 2321 Standard Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications • ASTM F 2620 Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings • ASTM D 2683 Standard Specification for Socket-Type Polyethylene Fittings for Outside Diameter- ADS HDPE drainage products are used in a wide variety of end-use applications: • Storm and sanitary sewers 1. • PE3408/PE4710 fittings have been qualified for fusion using ASTM D2657 generic fusion procedures. HDPE pipe shall be manufactured from extra high molecular weight polyethylene pipe materials meeting the requirements of ASTM D3350-96.

Pipe shall be manufactured to ASTM D3350-Standard Specification for Polyethylene Plastics Pipe and Fittings Materials Defines the raw materials requirements for all HDPE pipe. Where nonpressure pipe is specified, the fittings will be of the same or similar materials as the pipe and will provide the same durability and strength as the pipe. Pipe and fittings shall be made of high-density, high-molecular weight polyethylene material meeting the requirements of cell classification 324420C or higher in accordance with ASTM D3350.

Charter Plastics Black CTS tubing is made to ASTM D2737 Standards for outside diameter controlled pipe. The resin material will meet the specifications of ASTM D3350-05 with a cell classification of PE 445474C. standard thermoplastic material designation code of PE3408 and having a cell classification of 345464E per ASTM D3350.

” This product also meets Extra High Molecular Weight High (EHMW) Density Polyethylene for underground fire mains and loops, produced at a facility inspected and approved by the FM Research Corporation. feaTUres: hdpe 4710 ips & dips pressure pipe (8, 10”) Scope: This submittal designates the general requirements for High Density Poly-Ethylene Pressure Pipe from compound with a cell classification PE345464C as defined in ASTM Standard D-3350. 1 Polyethylene pipe is the only product identified in AWWA C906 with “Zero” leak requirement 2, 3 ORP = Oxidative Resistance Potential defined by ASTM D3350 and test method ASTM F1473.

ASTM D3350 Standard Specification for Polyethylene Plastic Pipe and Fittings Materials. 0 MPa. • Hydrostatic Design Basis 1,600 psi @ 73°F (23°C) and 1,000 psi @ 140°F (60°C) per ASTM D2837 • Color & UV Stabilizer: Black with 2% min Carbon Black per ASTM D3350 • Heat Fusion Joining as per ASTM F2620 and PPI TR-33/TR-41 • Installation as per AWWA M55 and PPI PE Handbook, 2nd edition ASTM F2160: Solid wall High Density Polyethylene (HDPE) conduit based on controlled Outside Diameter (OD).

Pipe grade polyethylene materials with the PE4710 designation describe a pipe grade material that meets exceptionally high performance requirements. ** Black material. org, or contact ASTM Customer Service at service@astm.

960 gm/cc – Melt Index (190°C/2. 20 (Plastic pipes); 23. ASTM D3330 | Adhesives | Peel Testing.

The nominal pipe properties were determined on pipe extruded from a pellet blend of TRB-432 and an approved carbon black concentrate. admet. Standard Specification for Polyethylene Plastics Pipe and Fittings Materials.

[100 to 250 mm] astm d2444 ASTM D3261 Specification for Butt Heat Fusion Polyethylene (PE) Plastic Fittings for Polyethylene (PE) Plastic Pipe and Tubing ASTM D3350 Specification for Polyethylene Plastic Pipe and Fittings Materials ASTM F4777 Standard Specification for Elastomeric Seals (Gaskets) for Joining Plastic Pipe AASHTO M45 Sand for Cement Mortar 445574C ASTM D3350 ^ Material has a chlorine resistance rating of CC0 (unspecified) per Table 2 of ASTM D3350. Designation: D 3350 – 08. A number in parentheses indicates the year of last reapproval.

ASTM D3350-10 Standard Specification for Polyethylene Plastics Pipe and Fittings Materials. (230 C) and 1400F. Formolene® E6210A High Density Polyethylene.

2) The Dimension Ratio (DR) is the specified diameter divided by the minimum wall thickness. Excavations for pipe bursting insertion or depression removal made between manholes. 040: Pipeline Components And Pipelines > 23.

in ASTM D3350. It is not the function of this specification to provide specific engineering data for design purposes, to specify manufacturing tolerances, or to determine suitability for use for a specific application. Test Method A – Single-Coated Tapes at a 180 Degree Angle.

PE4710, for example, means that the product is made of polyethylene with a “4” rated density, “7” rated slow crack growth class, and has a 1,000-psi maximum recommended HDS with a 0. PART 1: MATERIALS 1-1 PIPE: Select the pipe resin that apply A. 15 FLEXUrAL MoDULUS psi ASTM D790 110,000 to < 160,000 TENSILE STrENGTH psi ASTM D638 3500 to < 4000 SCG (PENT The ASTM D3350, “Standard Specification for Polyethylene Plastics Pipe and Fittings Materials” standard cell classification uses a series of digits to identify various properties of polyethylene pipe materials.

Only solid wall HDPE pipe in accordance with ASTM F714 shall be accepted. 3 m). View all product details ASTM D2412-Test Method for External Loading Properties of Plastic Pipe by Parallel Plate Loading ASTM D3350-Polyethylene Plastic Pipe and Fittings Material ASTM D2239-Polyethylene (PE) Plastic Pipe (SIDR-PR) Based on Controlled Inside Diameter ASTM D2447- Polyethylene (PE) Plastic Pipe, Schedules 40 and 80, Based on O.

All HDPE pipe shall be marked with a green stripe to signify its use for sanitary sewer utilities. 02 - Plastics (II): D 2383 - D 4322; ASTM International > By ICS Code > 23: Fluid Systems And Components For General Use > 23. ASTM F714, Standard Specification for Polyethylene (PE) Plastic Pipe (SDR-PR) Based on Outside Diameter.

All our fabricated HDPE fittings are manufactured from pressure rated polyethylene pipe grade feedstock made to ASTM F714. 2005 ASTM D 3350 Cell Classification Revisions ASTM D3350 Cell Class for Typical PE 3408: 345464C ASTM D2239 – Standard Specification for Polyethylene (PE) Plastic Pipe (SIDR-PR) Based on Controlled Inside Diameter ASTM D3035 – Standard Specification for Polyethylene (PE) Plastic Pipe (DR-PR) Based on Controlled Outside Diameter ASTM D3350 – Standard Specification for Polyethylene Plastics Pipe and Fittings Materials DIN Standards: Standard Test Methods for Measuring Adhesion by Tape Test1 This standard is issued under the fixed designation D3359; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. asTM d3350, standard specification for Pipe and fittings shall be made of virgin polyethylene compounds that comply with the cell classification 424420C for 4- through 10-inch (100 to 250mm) diameters, or 435400C for 12- through 60-inch (300 to 1500mm) diameters, as defined and described in ASTM D3350, except that carbon black content should not exceed 4%.

Pipe length shall be measured. Adhere the specimen to the testing plate. Polyethylene Plastics Pipe and Fittings Materials1.

Pipe shall be manufactured from a PE 4710 resin listed with the Plastic Pipe Institute (PPI) as TR-4. Pipe: All pipe is manufactured in accordance with the specifications set-forth in AWWA C906 “Standard for Polyethylene (PE) Pres-sure Pipe and Fittings, 4 inch (100 mm) Through 63 inch (1,600 mm), for Water Distribution and Transmission. 08 gm/10 min.

asTM d3350, standard specification for Installation shall be in accordance with ASTM D2321 and ADS installation guidelines, with the exception that minimum cover in trafficked areas for 3- through 24-inch (75 to 600 mm) diameters shall be one foot (0. the APWA/ULCC Color Code Standards. ASTM D3350 - 14.

Secure the tab to the static grip. ASTM-D3350 Standard Specification for Polyethylene Plastics Pipe and Fittings Materials - cell classification system; pipe and fittings material; polyethylene; recycled;; ICS Number Code 23. ASTM D2412-Test Method for External Loading Properties of Plastic Pipe by Parallel Plate Loading ASTM D3350-Polyethylene Plastic Pipe and Fittings Material ASTM D2239-Polyethylene (PE) Plastic Pipe (SIDR-PR) Based on Controlled Inside Diameter ASTM D2447- Polyethylene (PE) Plastic Pipe, Schedules 40 and 80, Based on O.

org. When provided, the metal threaded fastening rod shall be stainless steel. ASTM International > By Sections and Volumes > Section 8 - Plastics > Volume 08.

a. August 30, 1974 Standard Specification for Polyethylene Plastics Pipe and Fittings Materials This specification covers the identification of polyethylene ASTM D3350 : Standard Specification for Polyethylene Plastics Pipe and Fittings Materials Last previous edition approved in 2005 as D 3350 - 05. 01 GENERAL Article 1.

949 gm/cc – Density, Black D1505 0. ASTM D 1238: Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer g. This high density, high molecular weight polyethylene resin meets the standard for Type III, Class C, Category 5, Grade PE4710 piping material in The pipe is manufactured with an optional single-color stripe that are permanently extruded onto the pipe OD.

astm d3350

, , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ,